Technology Overview

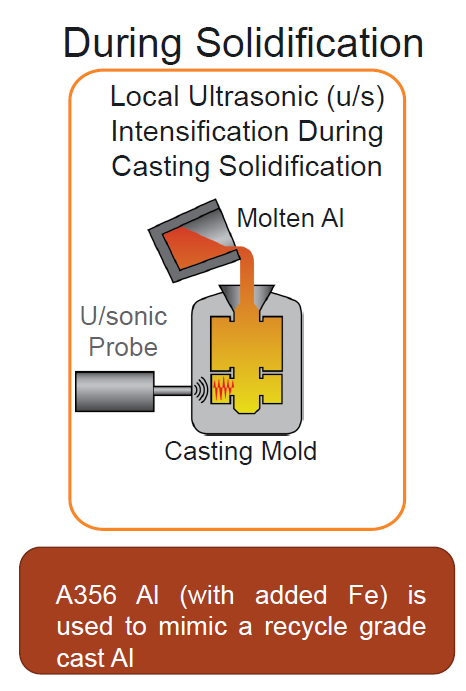

Aluminum (Al) castings are widely used in automotive and aerospace applications, and they offer cost-effective lightweighting opportunities. But their as-cast microstructures are typically dendritic and contain defects that reduce mechanical performance, especially when high levels of iron (Fe) are present, such as in recycled alloys. Researchers at Pacific Northwest National Laboratory have demonstrated a promising pathway to improve the mechanical performance of Al castings through the application of local ultrasonic intensification during the casting process.

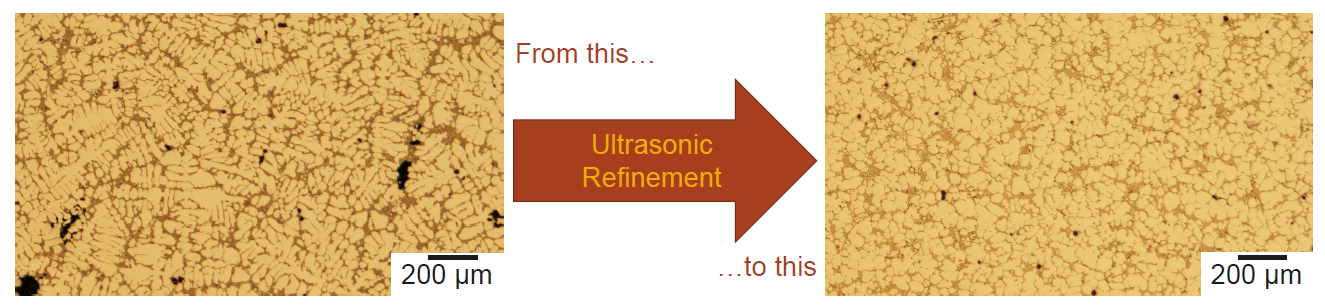

The ultrasonication process reduces the grain size by as much as ~90 percent, transforming conventional dendritic microstructures into rounded, unique, non-dendritic morphologies and reducing the aspect ratio shape of brittle intermetallic phases. The high-Fe aluminum alloy, which typically performs poorly, shows greater elongation upon ultrasonication, suggesting enhanced performance potential for recycled Al.

The ultrasonic intensification uses sound waves to reshape the metal grains as it solidifies. The ultrasound breaks up the normal dendritic structure, producing rounder grains that are more closely packed, while also reducing the severity of harmful, needle-shaped phases that otherwise weaken the alloy. Unlike conventional grain-refinement methods that rely on chills or chemical additions, the ultrasound process achieves refinement through mechanical and thermal effects of cavitation and acoustic streaming and allows better control without the need to alter alloy chemistry or add grain refiners.

DESIGN

Two molten aluminum alloys were cast into graphite molds: one with low Fe content (0.09 wt.%) and one with high Fe content (0.91 wt.%). An ultrasound probe was inserted during solidification, vibrating at 20 kilohertz. Resulting microstructures were analyzed using optical and electron microscopy, while thermodynamic simulations predicted phase formation. This design allowed direct comparison of ultrasonic effects across alloys with different Fe contents.

APPLICABILITY

This approach is applicable to automotive and aerospace industries, where lightweight components with high strength and ductility are essential. Ultrasound’s ability to refine high-Fe aluminum alloys makes it particularly valuable for recycling pathways without sacrificing mechanical performance and for reducing reliance on primary Al production.

Advantages

- Achieves grain refinement comparable or superior to that of chills or grain refiners.

- Maintains alloy chemistry, simplifying recycling.

- Mitigates harmful morphologies in high-Fe aluminum alloys.

- Significantly enlarges the zone with refined grains in high-Fe aluminum alloys.

For more information, please contact: commercialization@pnnl.gov