CINEMa Focus Areas

From concept to deployment, these focus areas are the scenes that make up CINEMa's vision for the future of nuclear energy.

Light-Water Reactor Materials

Focus Area Lead: Brady Hanson

The United States has 94 operating commercial nuclear reactors—all light-water reactors (LWRs) and almost all have had their original 40-year operating licenses extended by 20 years. A majority of the currently proposed small modular reactor (SMR) designs are LWR-based.

These bring technical challenges associated with fuels and materials. With the currently proposed LWR-based reactor designs the structures, systems, and components (SSCs) of the nuclear power plants need to serve longer service lifetimes, higher power output, and increased neutron and radiation damage. All SSCs, from the reactor pressure vessels to the reactor core and primary systems (such as steam generator tubes), plus the concrete, cables, fuel, and cladding either need new designs, improved materials, or innovative repair and mitigation technologies.

The Light-Water Reactor Materials focus area concentrates on pioneering transformative R&D to develop, characterize, and qualify advanced materials for existing and advanced LWRs. Pacific Northwest National Laboratory (PNNL) supports the nuclear industry in efficiently and rapidly deploying cutting-edge nuclear materials that enhance both safety and economic performance. At PNNL, we do this by combining premier capabilities with expertise in key areas including:

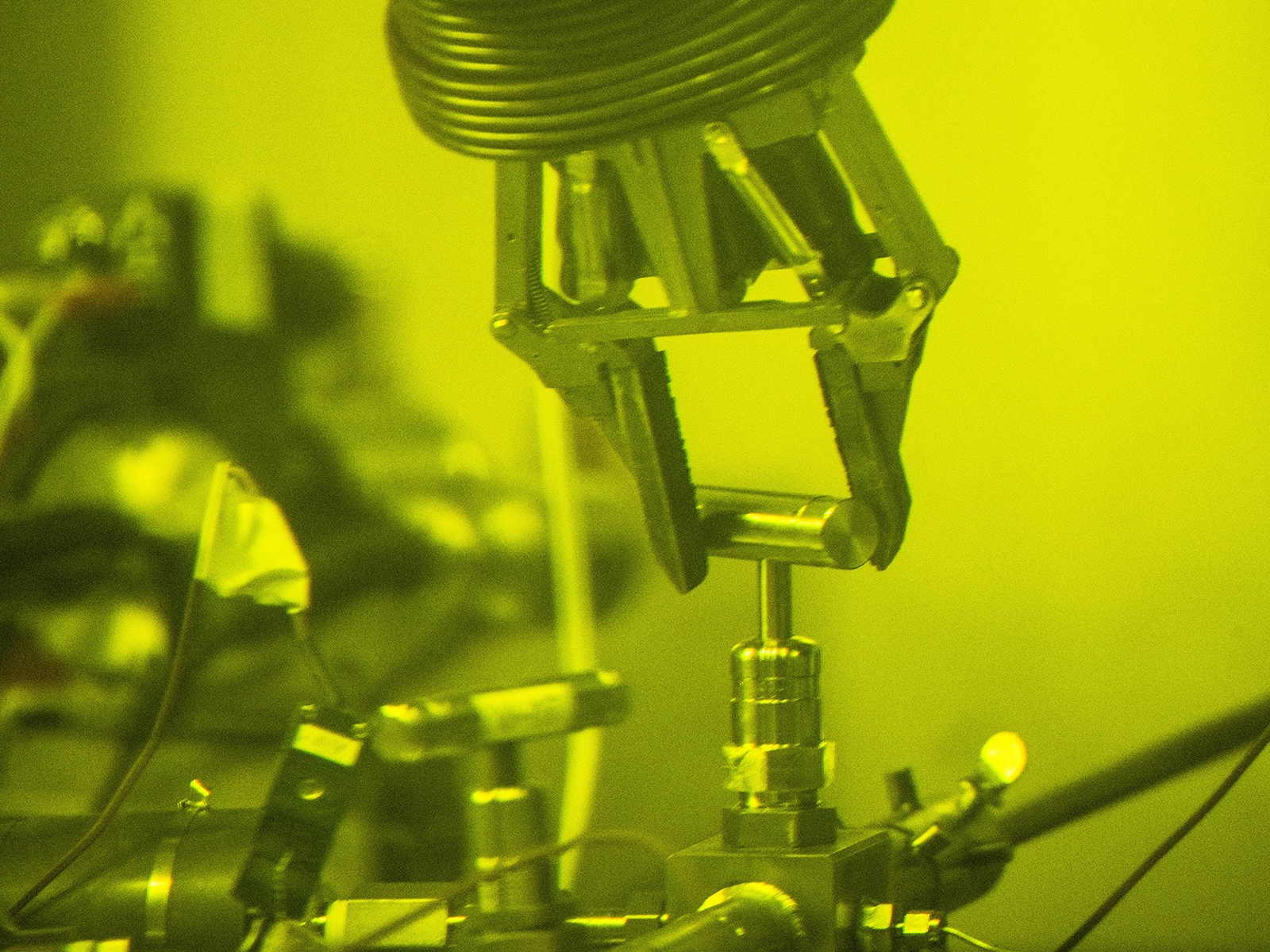

- Post-irradiation examination (PIE), microstructural and mechanical characterization of fuels and structural materials.

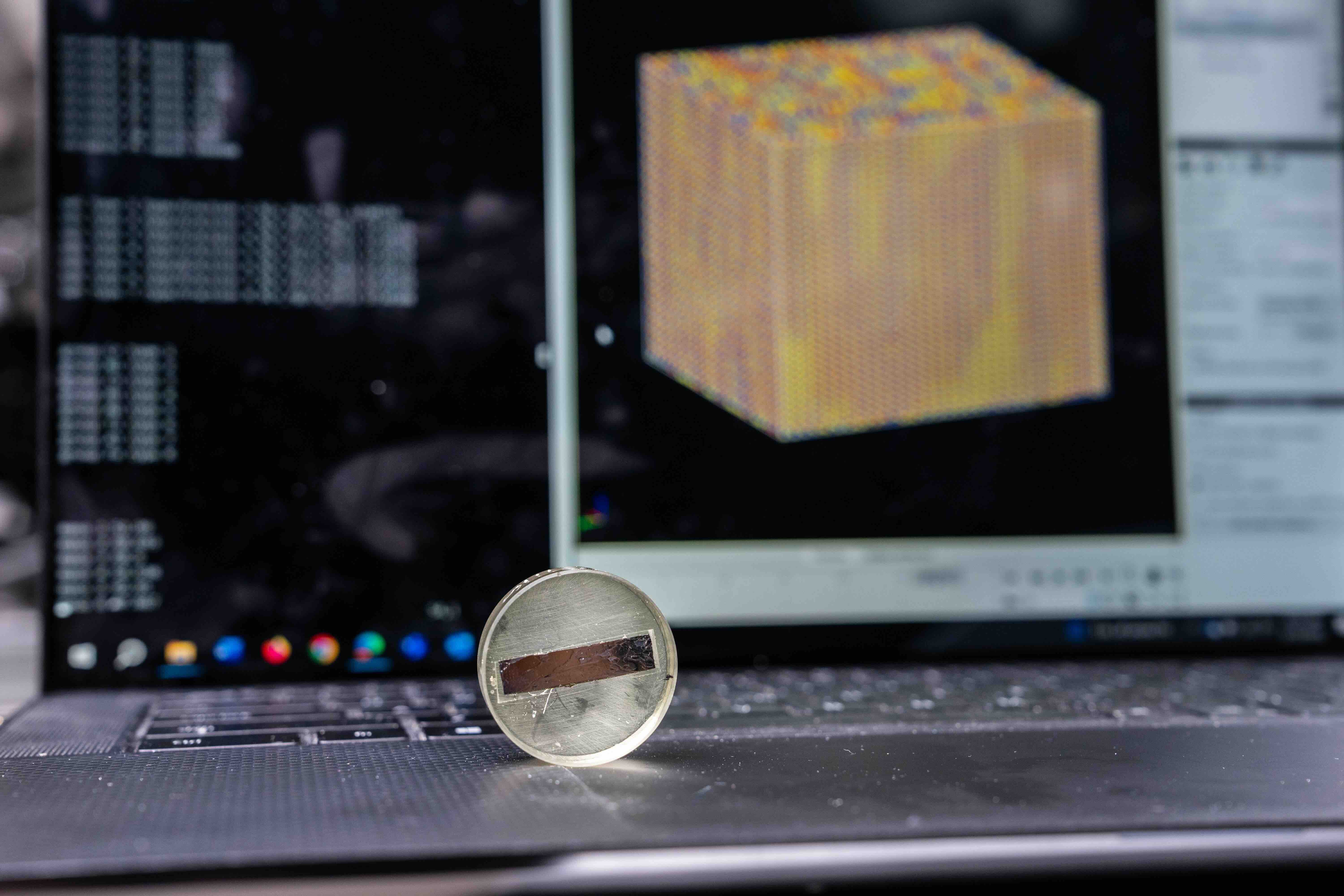

- Innovative testing and characterization methods—from atomic- to engineering‑scale—to accelerate qualification of materials prior to irradiation.

- Advanced materials development, leveraging capabilities from traditionally non‑nuclear mission areas.

- Advanced modeling and computational tools to assess ideas, prioritize approaches, and analyze prospective solutions.

Advanced Reactor Materials

Focus Area Lead: Stuart Maloy

The Advanced Reactor Materials focus area develops innovative and impactful research for the identification, characterization, and qualification of materials for advanced non-light water reactors.

This focus area supports the nuclear industry by providing PNNL's expertise in nuclear materials development, coupled with advanced characterization facilities to develop and test improved radiation tolerant materials for these extreme environments. By developing materials with improved performance in extreme environments, we aim to advance the deployment of non-light-water reactors such as molten salt, sodium, lead, and high-temperature gas.

R&D focus areas for fission and fusion reactors include:

- material identification and design

- material development

- component design

- material characterization

- material qualification

Integrated Nuclear Energy Materials Manufacturing

Focus Area Lead: Isabella van Rooyen

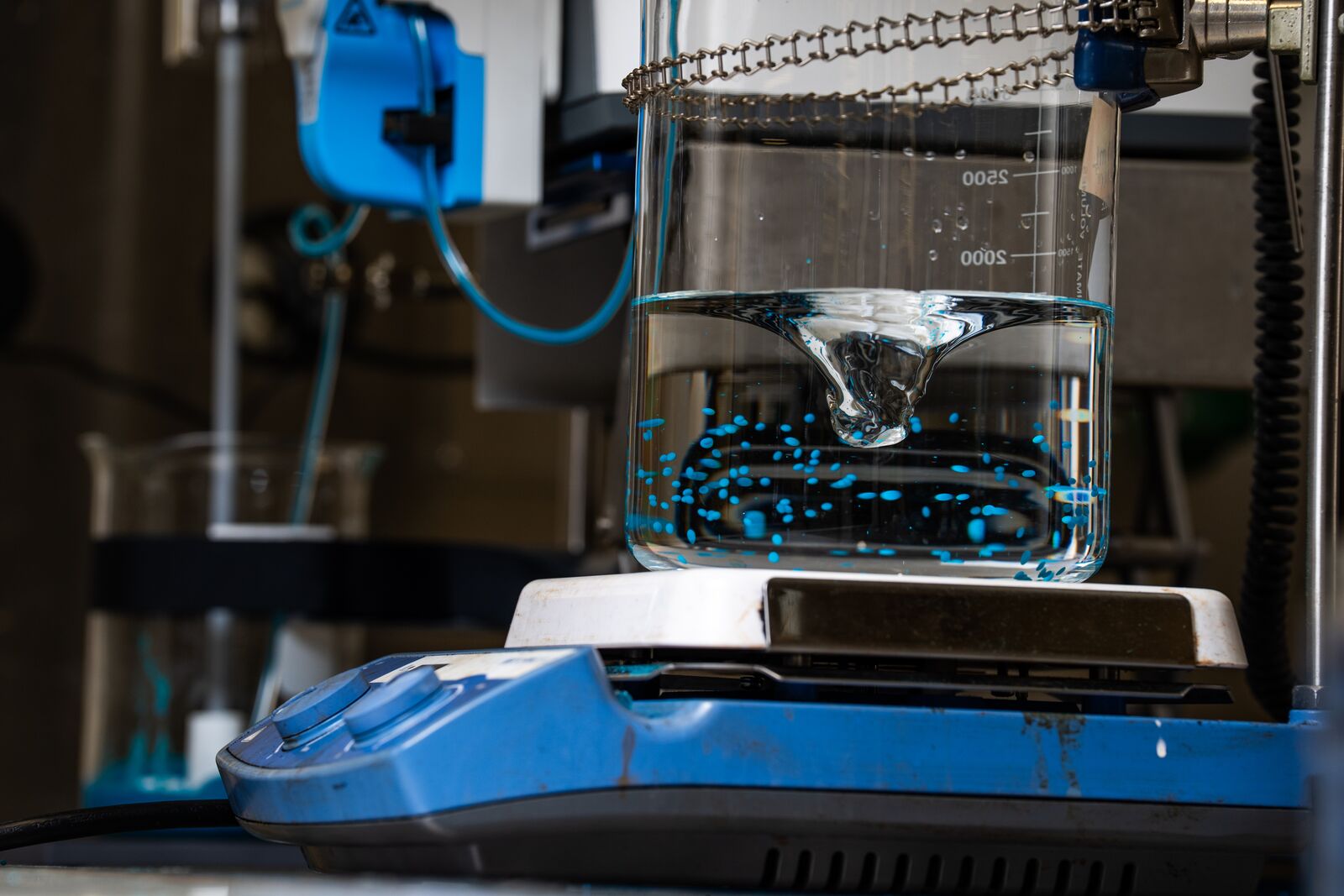

The Integrated Nuclear Energy Materials Manufacturing focus area is pioneering methods to leverage integrated material and component design for enhanced properties, through enabling multi-scale techniques to accelerate adoption within the full nuclear product lifecycle. Our objectives are to accelerate qualification of new material systems to meet the stringent demands of the nuclear energy industry, decrease the nation’s reliance on internationally sourced critical materials, and increase efficiency throughout the product and manufacturing lifecycle.

Our multi-disciplinary teams have customized solutions by integrating comprehensive material science expertise, proven applied experience in multiple manufacturing technologies, and tailored characterization with testing requirements through machine learning (ML) and modeling. By implementing smart methods of in-situ monitoring, streamlining inspection techniques, and applying new hybrid manufacturing techniques we help accelerate the development and testing process to enable rapid, relevant, and efficient decision-making and readiness for scale-up to deployment.

Unique to PNNL's advanced materials and manufacturing capabilities is the solid phase processing, wherein raw material product form and morphology are considered advantages for achieving performance due to the adaptability and reimagination through specialized sequenced or hybrid processes. Therefore, current supply chain constraints can be minimized through adaptability and flexibility of solutions.

The R&D focus areas which are leveraging artificial intelligence (Al)/ML include:

- material and method identification and design

- integrated material development

- multi-scale modeling and testing

- manufacturing, from lab-scale proof-of-concept to upscaling

- qualification processes

Fusion Energy Sciences

Focus Area Lead: Maria Sushko

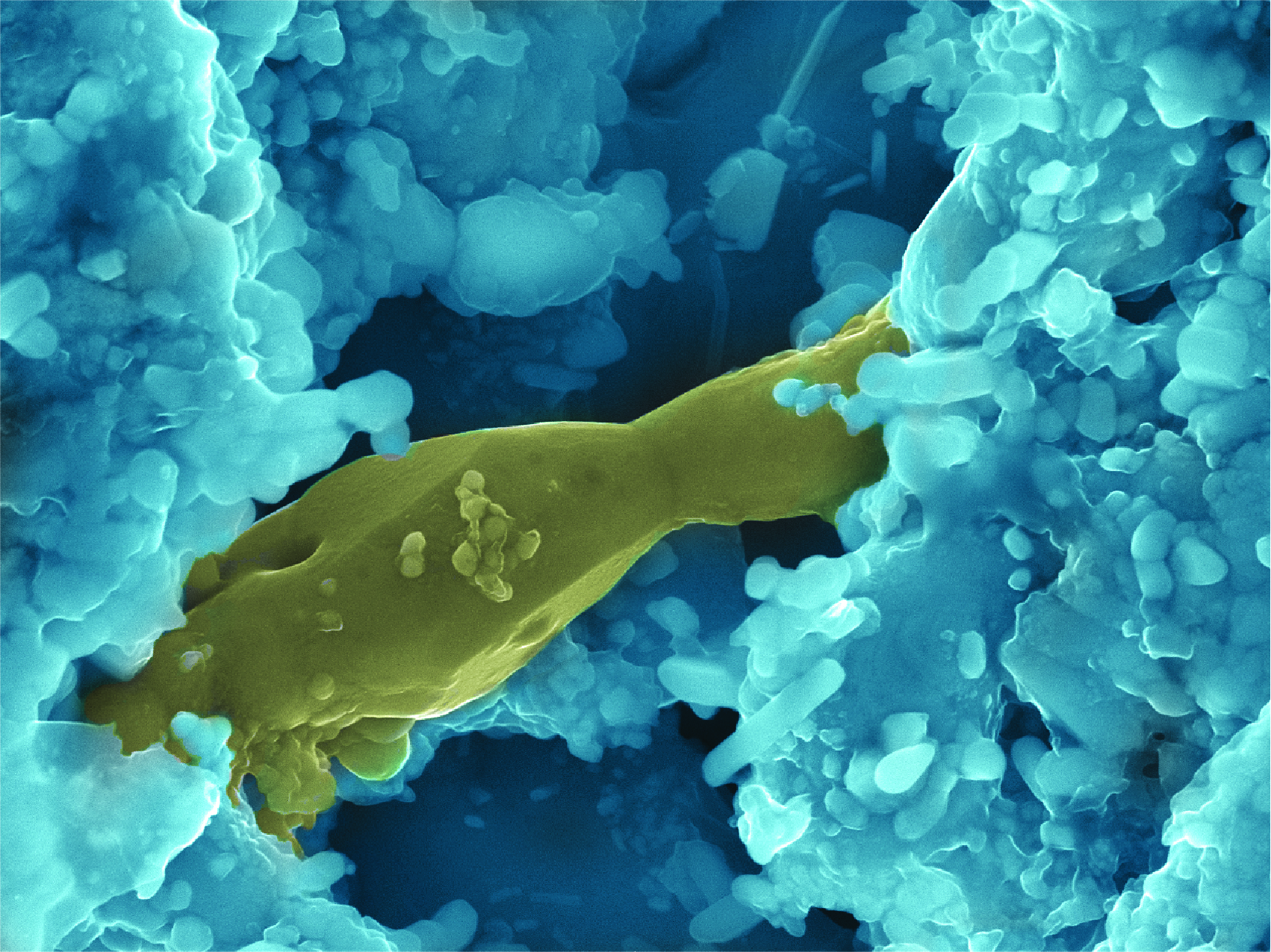

Fusion energy occurs when two nuclei combine in plasma, forming an entirely new atom in the process. Scientists at PNNL are working to harness the energy produced by fusion as an alternative form of power generation to produce electricity. Fusion reactors are limited by materials that can withstand the extreme conditions fusion creates.

PNNL’s unique scientific capabilities are helping advance fusion energy in several areas, including materials design for harsh environments, mechanical testing under realistic conditions, irradiated material handling and characterization, microscopy and microanalysis, tritium science, advanced manufacturing, high-performance computing, and machine learning.

PNNL’s research, which is supported by the Department of Energy, Office of Science, Fusion Energy Sciences Program, focuses on developing durable fusion energy reactor materials. PNNL is advancing the field of fusion reactor materials research through new techniques to develop materials that can withstand extreme operating conditions.

PNNL’s approach relies on a tight coupling between theory, experiments, and computation that leads to deeper insights into the performance of materials. PNNL leverages its solid phase processing capabilities to enable scalable, cost-effective fabrication of fusion reactor materials such as tungsten alloys and composites, oxide dispersion strengthened steel, vanadium alloys, nickel, and palladium coating. Each of these materials play a central role in fusion reactor design because they can resist radiation damage, erosion, and thermal shock.