PNNL Producing Cancer-Fighting Radioisotopes to Help Research Better, Faster Cures

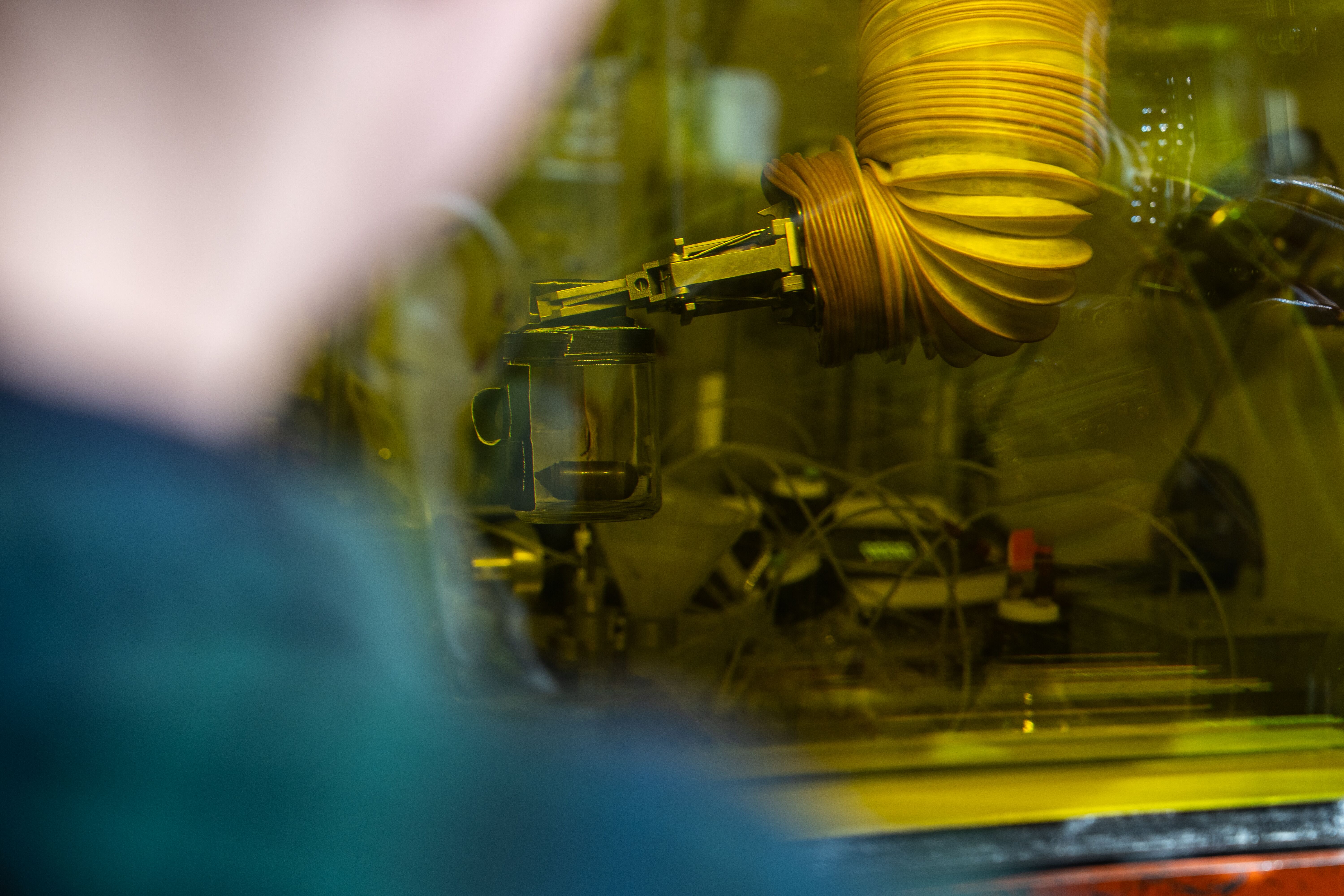

In support of the Department of Energy’s National Isotope Development Center, scientists Matthew O’Hara and Lucas Boron-Brenner use PNNL’s fully automated platform to produce radioisotope generators that allow lead-212 and bismuth-212 to be dispensed on demand and on location.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

When people in this community hear the words “radioactive materials,” the Hanford cleanup effort probably comes to mind. But for some researchers at the Department of Energy’s Pacific Northwest National Laboratory, working with radioactive materials involves safely and efficiently developing and producing medical radioisotopes. Radioisotopes—which are often critically needed and in short supply—are unstable forms of elements that emit radiation that can be directed to damage or kill cancer cells.

PNNL’s efforts directly support DOE’s Office of Isotope R&D and Production within the Office of Science, including the portions of its mission focused on producing and distributing radioisotopes, conducting innovative research and development on new production and processing techniques, and ensuring robust domestic supply chains.

Drawing upon expertise in radiochemical processing and separations, researchers at PNNL developed a fully automated platform to produce and assemble lead-212 and bismuth-212 radioisotope generators. The platform at PNNL’s Radiochemical Processing Laboratory performs the necessary complex chemical manipulations and radioisotope separations to produce these generators without human intervention.

With the help of automation, the enclosed, end-to-end production platform reduces worker exposure to harmful doses of radiation, allowing these generators to be prepared more frequently and at higher activity levels than methods requiring direct handling. The PNNL-produced radioisotope generators are then shipped to doctors and researchers around the world who use them to dispense these therapeutic radioisotopes on demand, at the point of use.

In a remarkable trash-to-treasure story, PNNL developed a technique to recycle valuable material from obsolete radioactive brachytherapy sources to create promising new therapeutic radioisotopes.

Radiochemists at PNNL are recovering radium-226 from brachytherapy devices in a variety of shapes and sizes that were designed to be implanted into a patient’s tumor, so it could bombard the area with radiation. Radium-226 is not used in treatments like this anymore, but it does hold exceptional value and serves multiple emerging applications. For example, it can be used as a target material to produce actinium-225, a powerful therapeutic radioisotope in high demand. Targeted therapies using this radioisotope are now in clinical trials due to their keen ability to precisely deliver cancer-killing radiation to tumor cells while sparing healthy tissue.

Given that radium-226 has a half-life of 1,600 years, the aging, outdated devices are a liability for those who still have them. They must be carefully managed because they could potentially harm people or the environment; they also pose a national security risk. Leveraging PNNL’s radiochemistry expertise and instruments in the Radiochemical Processing Laboratory, PNNL is one of a few places in the country that can extract radium-226 from those legacy devices, regardless of shape, size or chemical form of radium-226 they contain.

Researchers employ a custom-designed tool to cut open the small devices. They then collect and dissolve the tiny amounts of radium powder inside, remove impurities, and return it to a solid form that PNNL dispenses in small vials and ships to customers, in close coordination with the Office of Isotope R&D and Production’s National Isotope Development Center. This tedious process is done by workers using hand controls like a joystick to manipulate the instruments inside the hot cell that shields them from the radiation.

PNNL’s contributions related to radionuclides for cancer treatment began with a notable breakthrough in the 1990s, when researchers developed and licensed a safe and effective process to make ultrapure yttrium-90. This medical radioisotope is produced by separating it from its source, strontium-90, which is produced as a byproduct during fission of nuclear fuel in a reactor—including those used formerly to produce plutonium at Hanford. PNNL currently distributes strontium-90 for research and medical applications, also in close coordination with the National Isotope Development Center.

Looking ahead, PNNL will continue to leverage its world-class staff and facilities to advance the state of the art in isotope production. Their innovative methods for safe, efficient and effective handling of radioisotopes will help the nation meet the growing need for a dependable radioisotope supply, including those that bring better, faster cures for our loved ones.

Steven Ashby, director of Pacific Northwest National Laboratory, writes this column monthly. To read previous Director's Columns, please visit our Director's Column Archive.

Published: August 25, 2025