Materials Aging and Detection Science (MAaD Science) Laboratory

The Materials Aging and Detection Science (MAaD Science) Laboratory investigates the effects of production parameters, history, and service environment on the structure and performance of polymer and composite materials.

The Materials Aging and Detection Science (MAaD Science) Laboratory—located within the Physical Sciences Laboratory Building of Pacific Northwest National Laboratory (PNNL)—investigates the effects of production parameters, history, and service environment on the structure and performance of polymer and composite materials.

We use standard laboratory practices based on accepted consensus standards to quantify statistically significant material properties. Properties are correlated with material composition and extent of exposure to develop predictive understanding of material behavior in support of energy and security missions of the Department of Energy (DOE). DOE sponsors include the Office of Nuclear Energy, the National Nuclear Security Administration, and the Office of Energy Efficiency & Renewable Energy.

MAaD scientists evaluate the effects of elevated temperature, ionizing radiation, and other environmental stresses on polymer and device properties. Laboratory capabilities are also applied to polymer and composite recycling, upcycling, and sustainability applications. Simulation and correlation of measured effects of environmental exposure inform property and lifetime prediction. Example applications include electrical cable materials in nuclear power plants, plastics in single-use medical devices, and high-volume plastics to be recycled.

Capabilities

Characterization and testing

- Measurement of mechanical properties of polymers including tensile and flexural strength, hardness, and indentation modulus values.

- Assessment of physical properties such as density, surface energy, color, haze, and vapor transmission.

- Evaluation of polymer thermal behavior using techniques like DSC, DMA, and TGA.

- Use of Fourier-transform infrared spectroscopy (FTIR) and ultraviolet-visible (UV-vis) spectroscopy to analyze chemical bonds and optical behavior.

- Examination of electrical behavior and properties through dielectric spectroscopy, reflectometry, permittivity measurements, and tan delta measurements.

Accelerated aging

- Thermal and gamma radiation aging are applied to polymer materials to simulate the degradation experience under various operating conditions in nuclear power plants and other applications.

Dealing with uncertainty

- Design of experiments and statistical analysis are vital tools in making critical decisions regarding the behavior of polymer materials and determining their long-term effects.

Multi-physics simulation

- The multi-physics simulation capability is a finite element analyzer, solver, and simulation software package for various physics and engineering applications, especially coupled phenomena and multi-physics. This capability assists in simulating various conditions such as moisture, thermal, radiation, and other electrical conditions to validate the experimental results and predict adverse effects.

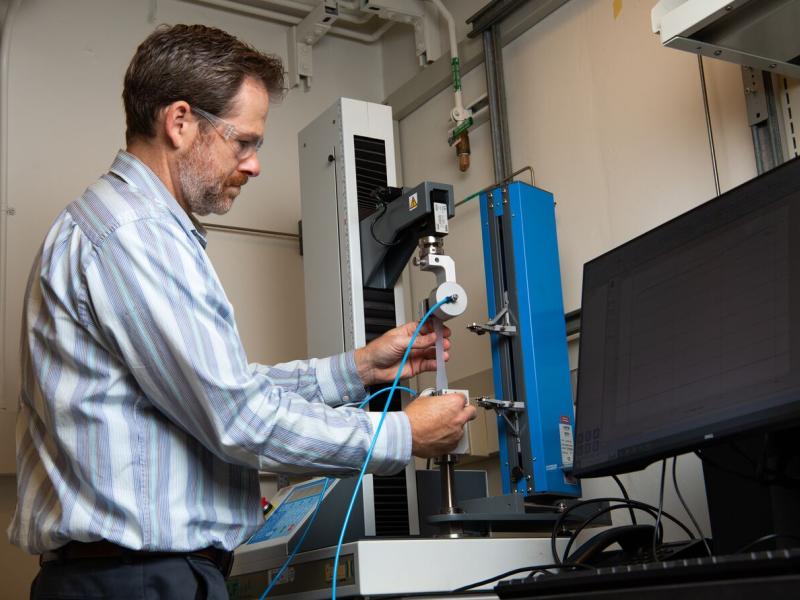

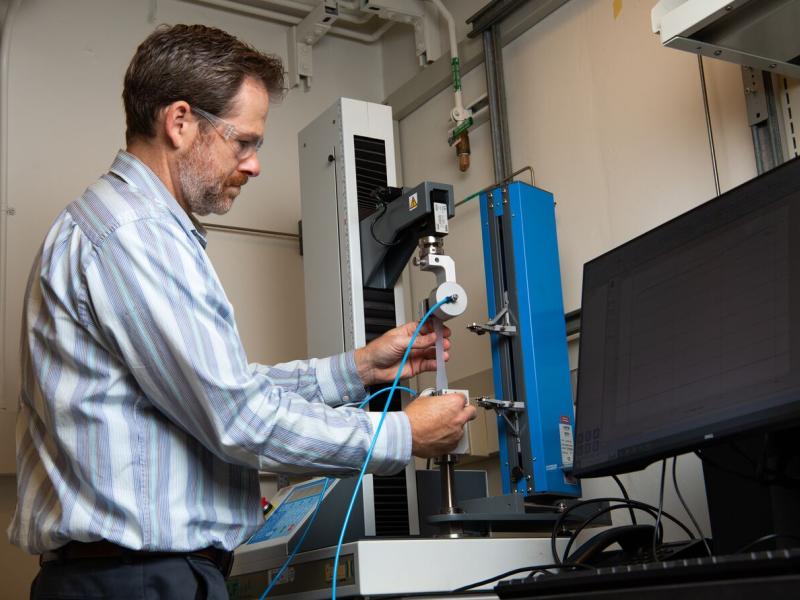

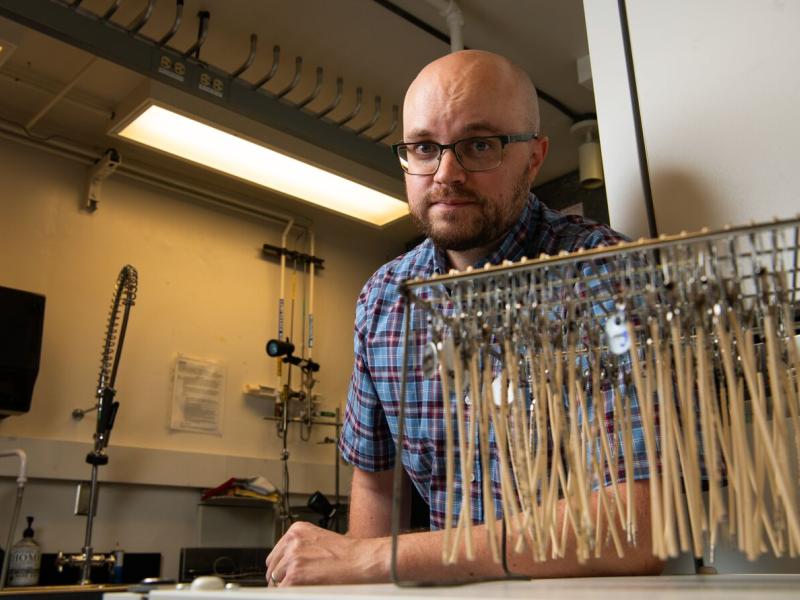

Leo Fifield measures mechanical properties of plastics, including elongation at break, strength, and stiffness, using a universal test stand (Chatillon LF Plus).

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

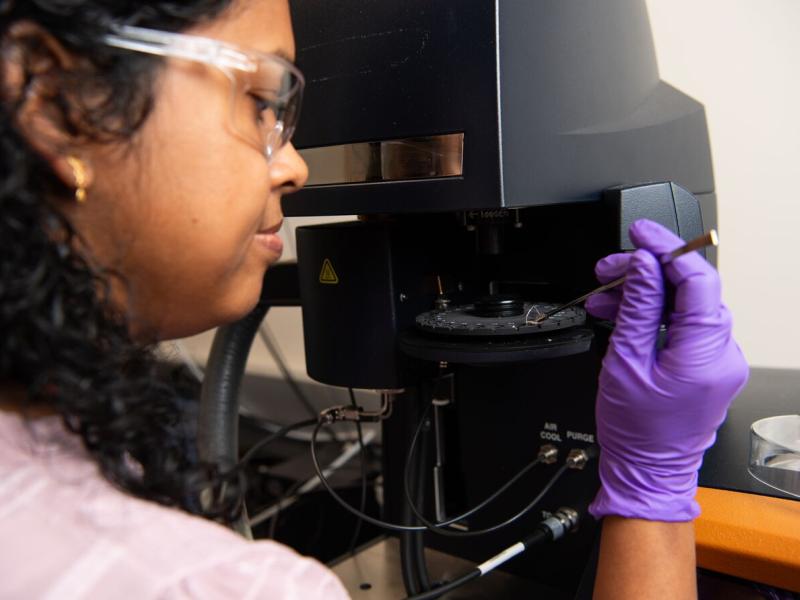

Sushmita Kumari measures the effects of exposure on phase transitions (e.g., melting point) and thermal stability of polymers using differential scanning calorimetry (DSC) (TA Instruments Q2000) and thermogravimetric analysis – mass spectrometry (TGA-MS) (TA Instruments TGA 5500).

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

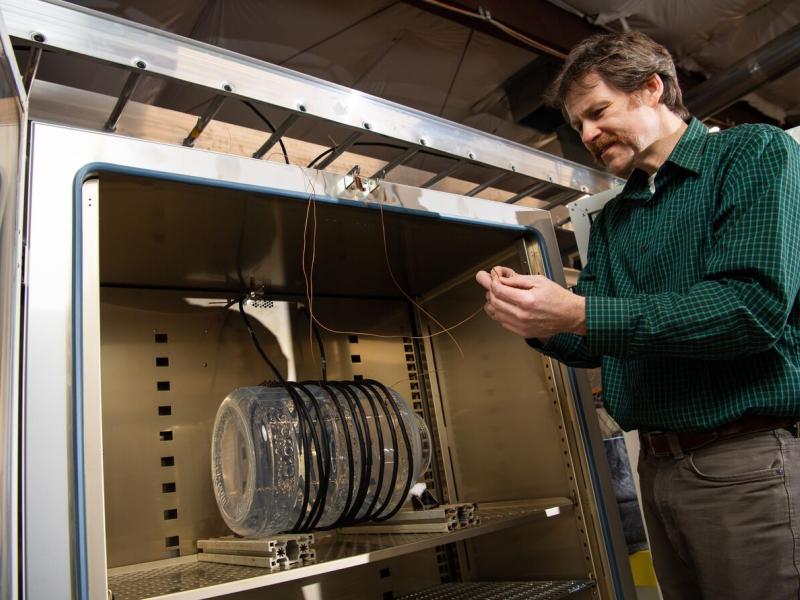

Tyler Tueller performs accelerating thermal aging of electrical cable insulation samples using advanced protocol mechanical convection ovens (Heratherm OMH180).

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Muthu Elen study the effects of service environment on the structure and performance of electrical insulation in support of continued safe generation of electricity by existing nuclear power plants in the United States.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Vishal Kumar uses a Fourier transform infrared spectroscopy microscope (Bruker LUMOS II) to investigate the chemical bonds present in microscale features of polymer surfaces.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Example Equipment

Mechanical

- Instron 3367 Mechanical Test Equipment (1KN, 30KN load cell, and 1 KN, 10 KN pneumatic grips)

- Nanoindentation equipment

- Torque tester

- Hardness (Shore M, Shore D)

- LFPlus Chatillon Pull-out Tester (1KN loadcell with pneumatic grips)

- Taber Abraser Model 5135

- Reciprocating Tribo Tester (used to determine wear rate, coefficient of friction)

Chemical

- Agilent Cary 5000 UV Vis NIR

- Bruker Alpha II FTIR

- Bruker LUMOS II FTIR Microscope

- Caron Environmental Chamber

- Kruss Mobile Surface Analyzer

- Olympus Optical microscope

- Hazemeter

Thermal

- Differential Scanning Calorimetry (DSC) Q200

- TA TGA 5500 – Mass Spec

- Dynamic Mechanical Analysis (DMA) Q800

Electrical and nondestructive evaluation

- Omicron Lab Spectano 100 Dielectric Analyzer

- Copper Mountain TR1300 Vector Network Analyzer

- LIRA equipment

- HV Diagnostics Tan Delta Equipment

Computational software

- COMSOL Multiphysics