Critical Minerals Laboratory

United States

Critical minerals are essential to the U.S. economy and national security. The Critical Minerals Laboratory at Pacific Northwest National Laboratory is focused on developing approaches to extract these minerals from low-grade ore bodies that are currently uneconomical or inaccessible with existing technologies.

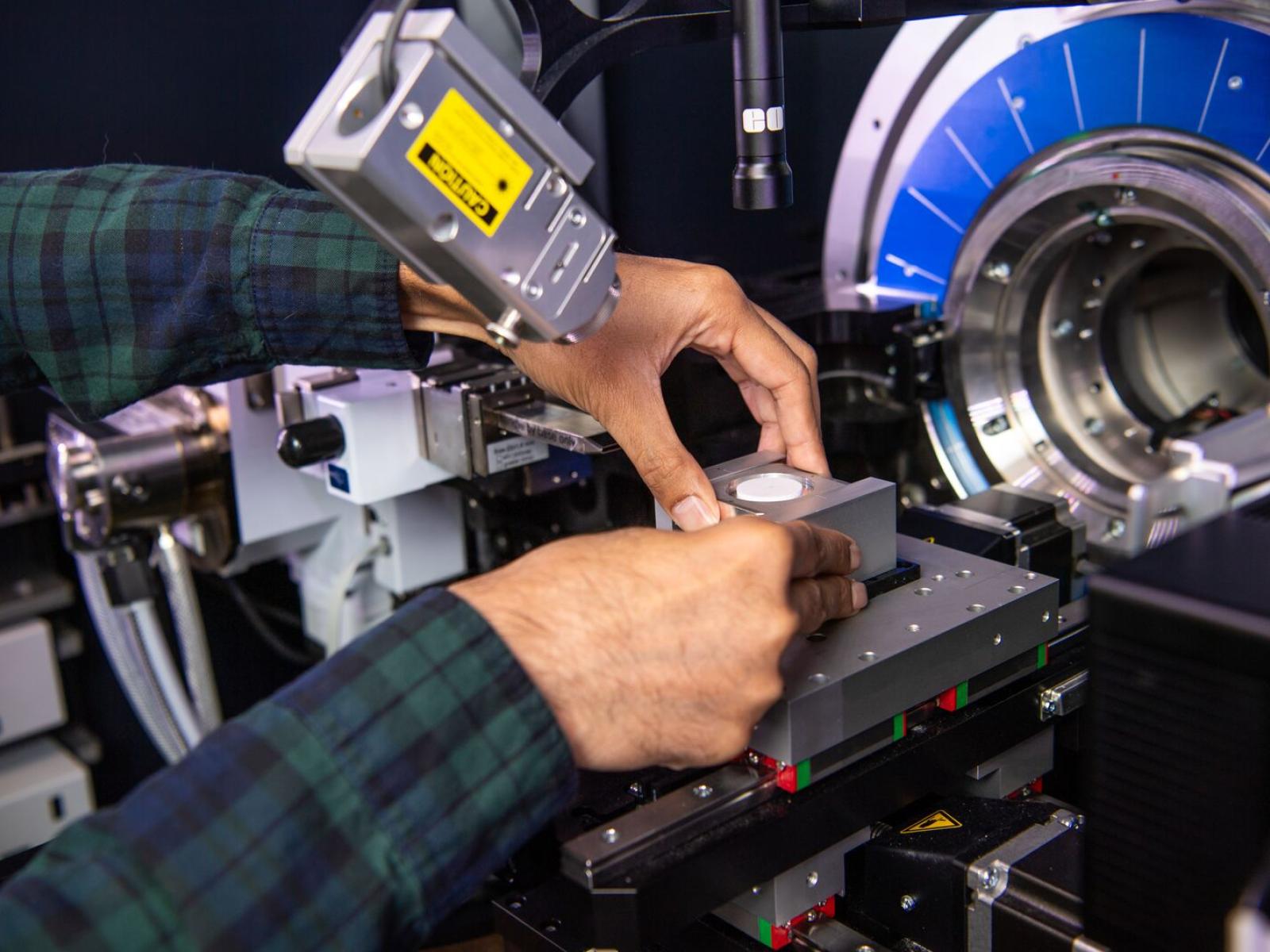

The laboratory space includes an X-ray diffractometer (XRD), micro-X-ray fluorescence spectrometers, automated mineral mapping, X-ray microtomography, thermogravimetric analysis with mass spectrometry, engineered fluid testing processes, seismic core testing capabilities, a large collection of hydrothermal reaction vessels, in situ flow-through reactors, field-deployable Raman, and a total reflection X-ray fluorescence (TXRF) spectrometer.

Core to the work in the Critical Minerals Laboratory is a world-unique XRD setup that enables the team to understand mineral reactivity and phase evolution during reaction with the engineered fluids used to extract critical minerals. This instrument enables precise tracking of phase evolution under field-relevant temperatures and pressures. Additional XRD capabilities in the laboratory include:

- High-throughput Bragg–Brentano powder XRD for rapid phase identification and quantification, lattice-parameter shifts, and crystallinity metrics—ideal for ore typing and in situ critical mineral recovery feedstock screening.

- Micro-XRD with Montel optics for point scans on cores, chips, or thin sections of material to map heterogeneity, alteration fronts, and localized scale or armoring without requiring destructive sample preparation.

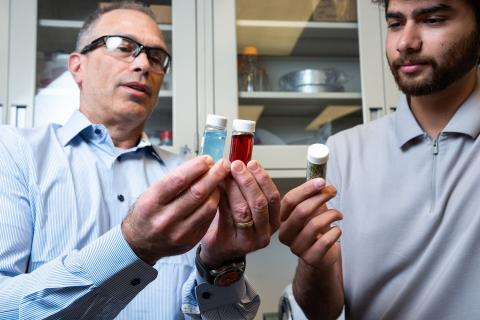

TXRF is another important capability in the Critical Minerals Laboratory. TXRF is a specialized high-sensitivity, nondestructive X-ray fluorescence technique that measures trace elements at the parts-per-million to parts-per-billion level. The instrument in the Critical Minerals Laboratory is also field deployable. It requires minimal sample preparation and uses total reflection to reduce background noise, making it highly suited for understanding critical mineral concentrations down to the parts-per-billion level for in situ mining of unconventional assets.

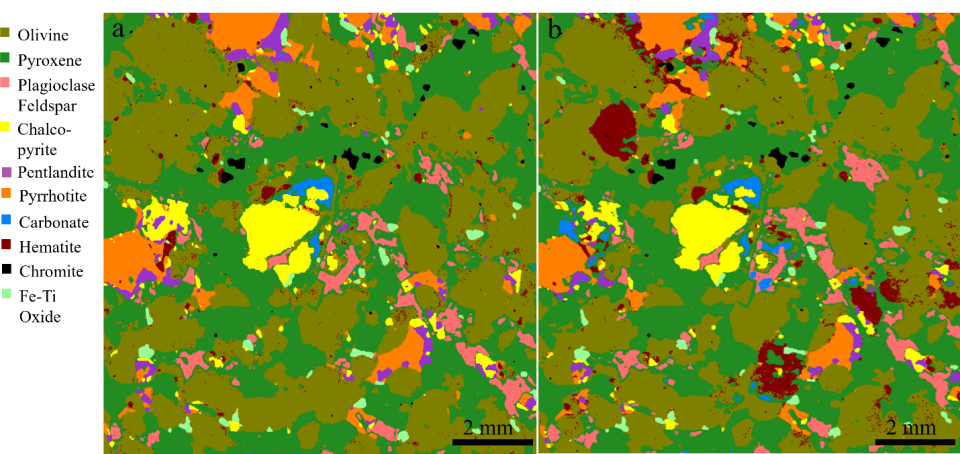

X-ray fluorescence (XRF) enables rapid, nondestructive, and multi-elemental analysis of solid samples, allowing precise determination of major, minor, and trace element compositions. This capability is key for identifying and quantifying a range of elements in ores, rocks, and processing residues, supporting efficient resource assessment for critical minerals. Paired with automated mineral mapping and quantification software, XRF can provide valuable information on both the spatial distribution and geochemistry of target resources.

X-ray microtomography (XMT) provides nondestructive, high-resolution 3-D visualization of ore and rock samples. This allows scientists to precisely map their internal microstructure and quantify key characteristics. These 3-D relationships reveal pore networks and how fluids will flow through the rock to dissolve and recover the target minerals. XMT can also be coupled with an in situ high-pressure, high-temperature X-ray-compatible core-flooding system to nondestructively visualize 3-D fluid–rock interactions under realistic industrial or geological conditions. By observing dynamic processes like in situ leaching or reactive fluid flow in real time, researchers can directly see how, where, and how fast target minerals are dissolved and transported through the rock’s pore network. This fundamental understanding is essential for optimizing extraction efficiency and developing new, more effective recovery technologies.

The lab also contains a large assembly of more than 70 high-pressure and -temperature Parr vessel reactors. These vessels are used to simulate subsurface conditions for fluid–rock interactions between target ores and unconventional resources with injected engineered fluids. A wide array of laboratory ovens allows for tuning the temperature to determine reaction rates and kinetics.

Parr vessel experiments are also supplemented with experimental reaction capabilities at ambient pressures and elevated temperatures using glass vials in heating blocks to rapidly screen engineered fluids. These short-term scoping reactions allow for fast determination of the compatibility and success of fluid–rock interactions to mobilize target critical minerals.

Beyond these core capabilities, the lab contains other key instrumentation for critical mineral research:

- Field-deployable Raman spectrometer for mineral identification.

- Thermogravimetric analysis with mass spectrometry to determine volatile mineral contents, which is particularly well-suited to determining the success of in situ separations products during fluid–rock experiments.

- A gas chromatography system, which enables precise quantification and differentiation of hydrogen and other gases (CO, CO₂, CH₄) generated during chemical reactions.

- Seismic core testing, also known as the “mini earthquake machine,” for evaluating how nanoparticles alter subsurface geophysical properties and monitoring the flow of injected fluids.