CDI Project: Performance Prediction and Process Attribution for Additive Manufacturing

Return to Additive Manufacturing Use Case

PI: Chris Barrett

Project Team: Zack Kennedy, Tim Pope, Tamas Varga, Anil Battu, Sef Christ and Michelle Fenn

Project Term: October 2018 to September 2020

Key Science Questions:

- Can signatures of additively manufactured parts be correlated from build through to use?

- What is the extent to which XCT can be used in porosity determination?

- How does porosity impact a part’s chemistry, material structure, and mechanical performance?

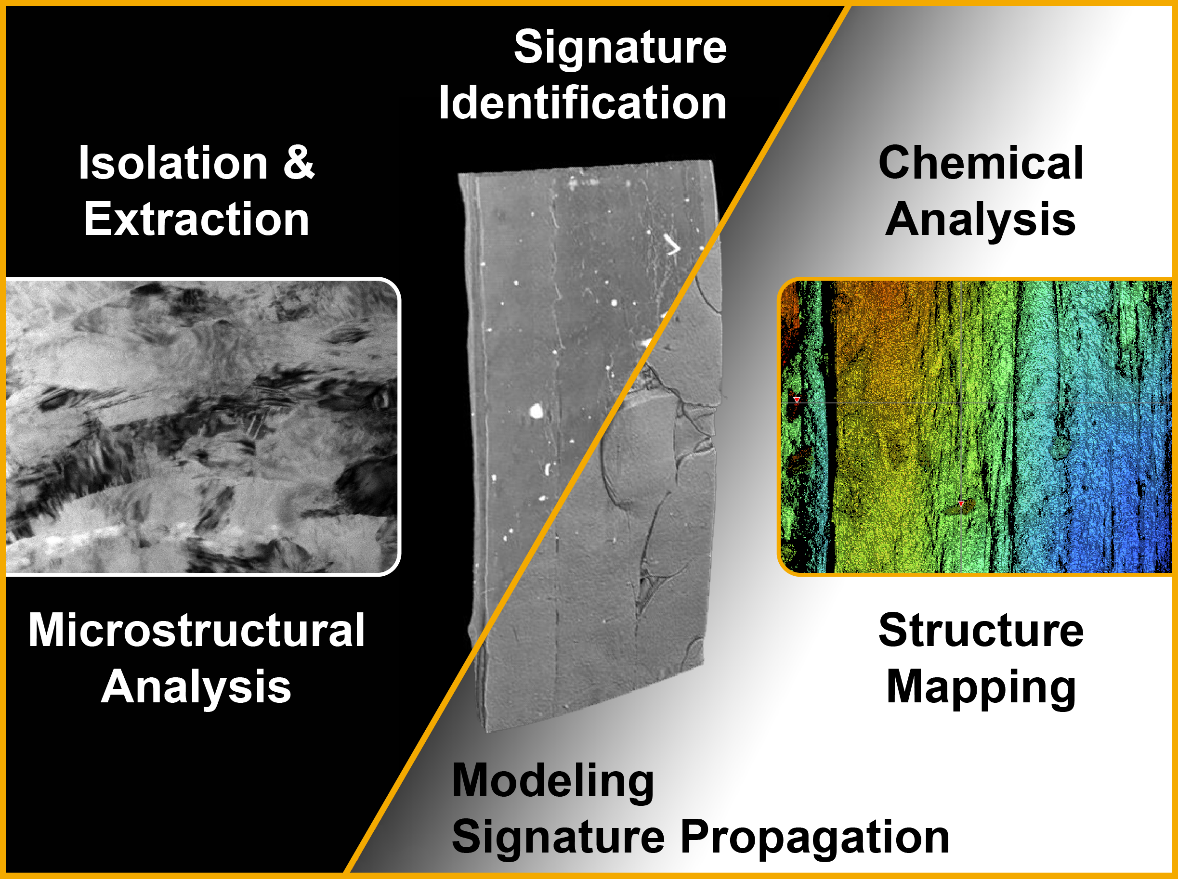

Project Description: The purpose of this project was to develop a focused capability to address the need for additively manufactured device forensics, identify signature rich aspects of different build processes that can be used to distinguish counterfeits, and to determine provenance and predict performance.

The rise of additive manufacturing (AM) in recent years is, in part, due to the open-sourced nature of the printing processes and reduced cost and capital barriers relative to traditional manufacturing. The advent of “desktop” 3D printers has, quite literally, brought manufacturing to the masses. Thus, it is reasonable to assume that AM will lead to an increase in objects of importance to national security, which could be fabricated at a point of use, and to global markets, where an influx of parts and products of unknown origins could lead to rapid destabilization. This democratization of manufacturing has spurred a growing demand from producers and end-users to verify the authenticity and quality of individual parts.

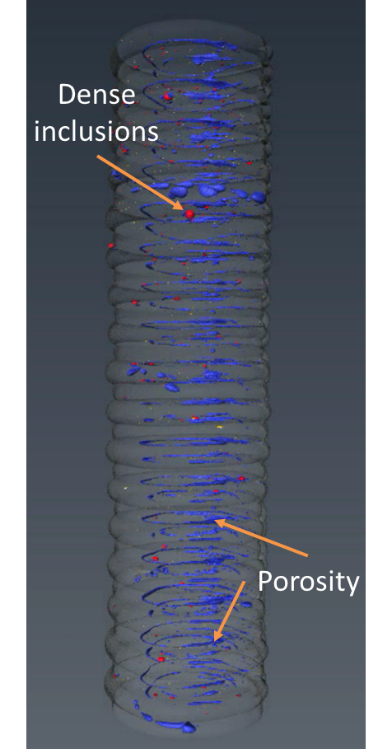

Under this project, we are investigating the use of advanced measurement techniques to study unique structural and chemical characteristics within AM objects. Some of our initial efforts have centered on X-ray computed tomography (XCT). This non-destructive evaluation technique allows for the examination of microstructure within an object, with little need for sample preparation. This capability allowed us to study unique artifacts of a build process, such as porosity, density variations, and particulate incorporation. For instance, the porosity of an SLS-printed object has been found to correlate directly with build direction. At the same time, filament materials of FDM systems exhibit significant incorporation of high-Z metals or metal clusters as a result of both extrusion and printing. Under the framework of an RSI and based on the strength of the results gathered from this project, and SEM integrated µCT was procured and installed at RPL, allowing at an expansion of this technique to smaller length scales (sub-micron).

Coupling techniques, such as computed tomography, focused ion beam milling, and electron microscopy, particles embedded during FDM printing were successfully mapped, extracted and then isolated for discrete analysis by STEM and EELS. In addition, pyrolysis gas chromatography-mass spectrometry was tested and evaluated as an ideal technique for not only polymer identification in SLS prints, but also for detection of trace additives and impurities that can be sourced to specific printer feedstock and their associated supplier.

Building upon our established expertise and capabilities with measurement and trace detection, the ultimate goal for this research going forward will be to focus more heavily on a model-prescribed measurement strategy that is tailored to phase-field and finite element analysis, affording better correlation between the two areas, and greater insights from data analytic techniques. In this way, more applied science challenges from various sponsors could be tackled more holistically.

Project Publications:

- Kennedy ZC, J Christ, B Arey, L Zhong, C Barrett. 2019. “Tunable Porosity in Fused Filament 3D-Printed Blends of Intrinsically Porous Polymer and Thermoplastic Aliphatic Polyesters Polycaprolactone and Polylactic Acid.” ACS Applied Polymer Materials, 1 (3), 482-492, 10.1021/acsapm.8b00172