Technology Overview

The Magnetically Coupled Loading Chamber is a groundbreaking sample chamber holder designed for magic angle spinning nuclear magnetic resonance (MAS NMR) spectroscopy. This innovative chamber operates efficiently under both high and low pressures, overcoming significant barriers with in situ sample analysis. Its unique magnetically coupled rotation mechanism promises greater control and precision, enhancing the reliability and effectiveness of sample testing under varied pressures and conditions.

The analytical instrumentation industry consistently faces the challenge of maintaining sample integrity under varying pressure conditions during in situ MAS NMR analysis. Traditional devices struggle to keep samples under vacuum and at low pressures, which often leads to compromised results and inefficiencies. These pain points hinder researchers and industry professionals from achieving precise and reliable data.

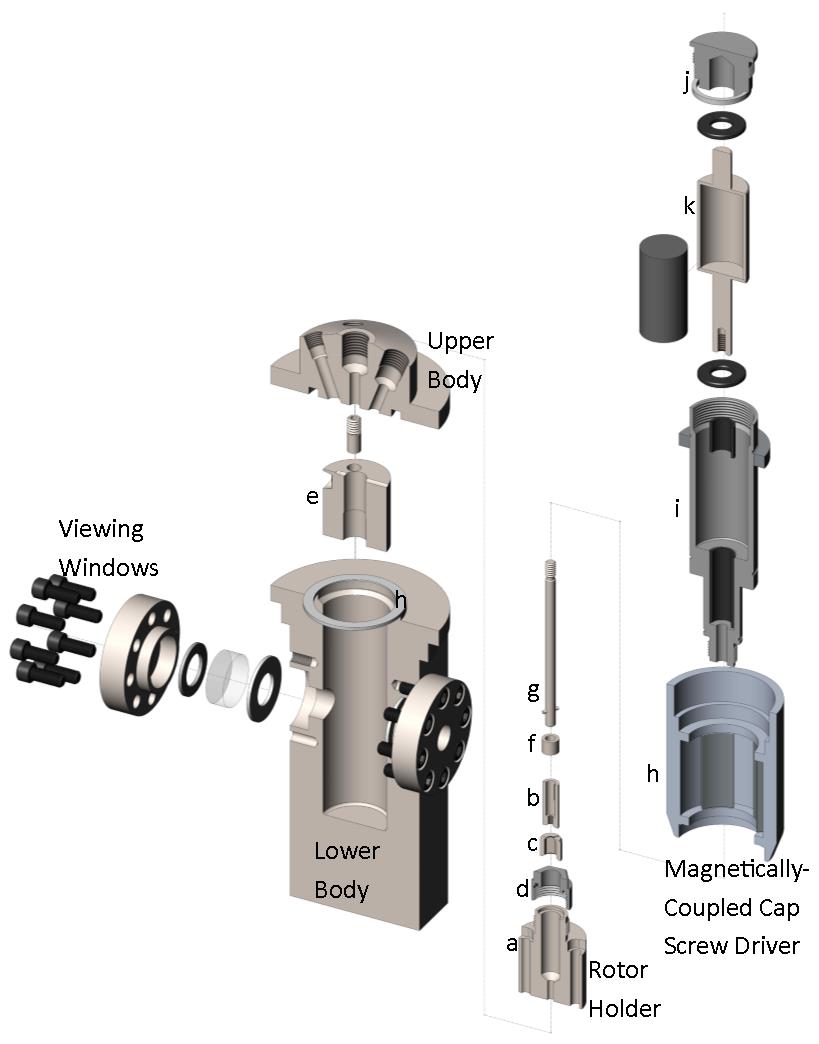

Developed at Pacific Northwest National Laboratory, this advanced technology addresses these issues by offering a solution that can maintain a seal under vacuum while allowing sample preparation at both high and low pressures. The core functional principle is a magnetically coupled rotation member, which operates within a high-precision sample chamber. This member ensures that an NMR cap can be opened or sealed in situ without disturbing the NMR rotor's position. The chamber can operate under pressures from vacuum conditions up to 2,000 psig and can be externally heated, further enhancing control over the sample environment.

Pacific Northwest National Laboratory scientists have engineered this technology with a modular design, including viewing windows for real-time observation and multiple entry ports for gas flow and temperature monitoring. The impact on the industry includes improved operational reliability, reduced time and cost in sample analysis, and enhanced safety and control over the testing environment.

APPLICABILITY

This technology can be utilized across various sectors within the analytical instrumentation industry. Prospective users include research laboratories, academic institutions, industrial research and development facilities, and manufacturers of MAS NMR equipment.

DESIGN

A loading device that is capable of operating for both low and high pressure comprises of a holder for statically mounting an in situ rotor therein and a magnetically coupled rotation member that engages and rotates the sealing cap of the NMR rotor, providing sealing or opening of the cap in-situ while the rotor remains statically positioned in said device.

Advantages

- Enhanced control: Precise manipulation of sealing and opening NMR caps in situ without disturbing sample positioning.

- Versatile pressure operations: Capable of operating under both high and low pressure, from vacuum to 2,000 psig.

- Improved reliability and safety: Elimination of moving parts as sealing surfaces, reducing the risk of leaks and over-tightening.

- Modular design: Adaptable to different rotor sizes and equipped with multiple ports for gases and temperature control.

For more information, please contact: commercialization@pnnl.gov