Technology Overview

Shear Assisted Processing and Extrusion (ShAPE) is a next-generation direct and indirect extrusion technology developed at Pacific Northwest National Laboratory (PNNL) that uses friction-generated heat from a rotating die to soften and extrude feedstock without the need to preheat the entire billet in a furnace. The extreme deformation imparted by ShAPE creates products that often cannot be created through conventional manufacturing, opening the door to domestic manufacturing of products with superior performance or properties in several critical sectors—national security, energy, transportation, and others.

Leveraging this breakthrough ShAPE technology, PNNL has now developed ShAPEretro—a ShAPE retrofit system that could enable existing extrusion press lines to be transformed into advanced, high-performance ShAPE production systems without the need to replace their existing capital-intensive infrastructure. ShAPEretro is designed to integrate seamlessly with conventional extrusion presses, allowing manufacturers to unlock ShAPE’s unique performance benefits—such as the ability to upcycle low-cost materials and reduce critical material use, produce ultra-conductive alloys, and process materials that cannot be extruded with conventional extrusion systems—while preserving their existing equipment capital investments.

Rotating the die while simultaneously applying high axial loads introduces engineering challenges: Conventional extrusion presses are not designed to rotate the die and transmit torque under combined and controlled rotational and compressive forces.

To ensure seamless integration, ShAPEretro addresses the challenge by bringing ShAPE capabilities directly to the existing fleet of extrusion presses through a mechanical architecture that deliberately separates the torque path and die rotation functions from the linear extrusion motion. The extrusion press supplies axial force, while the module independently manages rotational torque and alignment, with the two systems engaging only during extrusion.

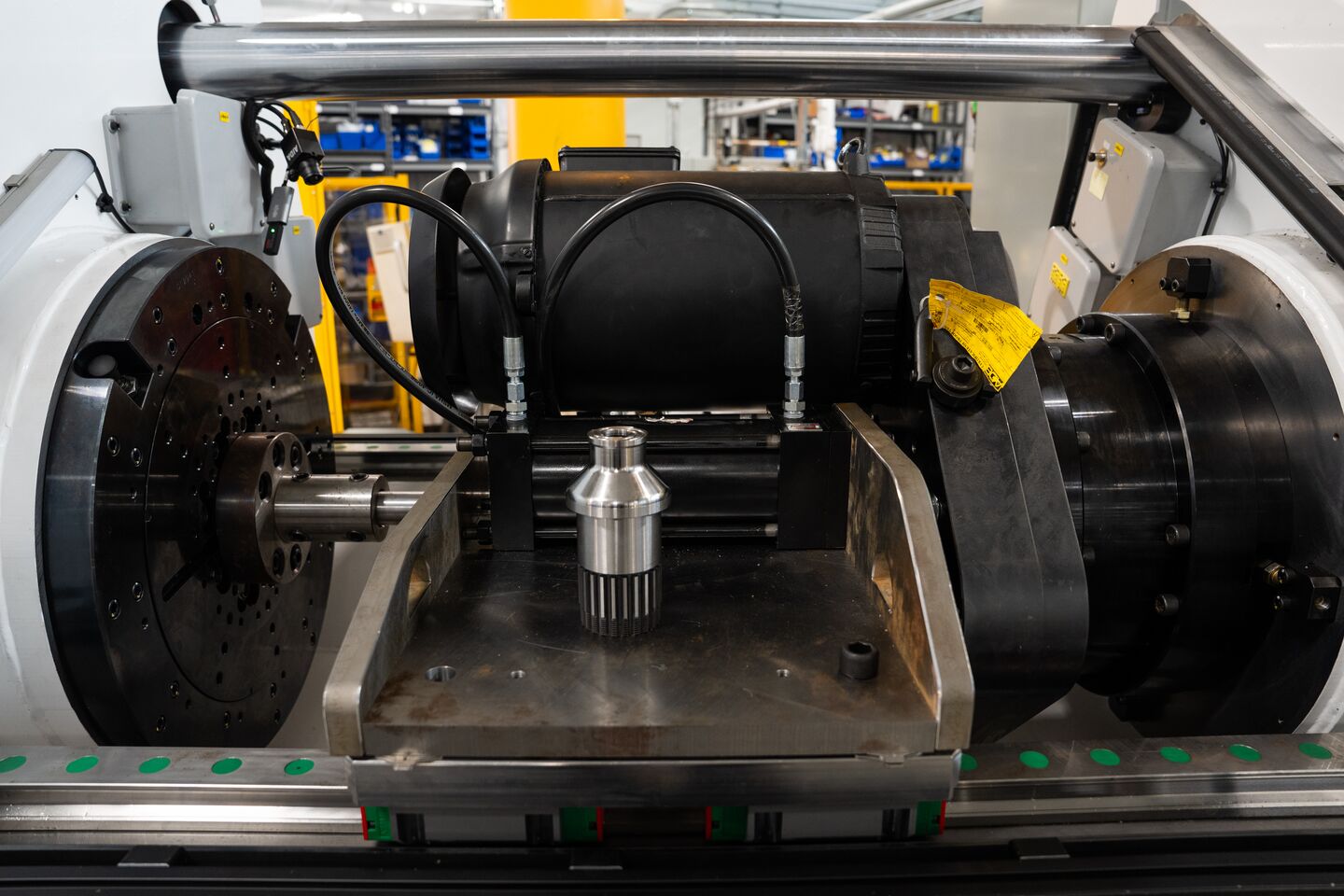

The module shown represents a demonstration implementation of ShAPEretro for retrofitting existing extrusion presses. While the final system configuration will vary by press and application, implementations would preserve the same separation of torque path, axial load, and alignment functions.

APPLICABILITY

ShAPEretro can be deployed across sectors requiring high-quality metal extrusions. Manufacturers can adopt advanced ShAPE processing with very little capital investment, enabling lower energy consumption, fewer processing steps, and improved microstructure control. For example:

- Automotive: Crash-resistant, lightweight components.

- Aerospace: High-strength, low-mass profiles.

- Construction: Improved structural elements with lower embodied energy.

- Industrial Manufacturing: Extrusions requiring superior mechanical performance.

- National Security: Novel alloys and secure supply chains for critical materials.

- Energy: Ultra-conductive grid components such as cables, busbars, and transformers.

For more information, please contact commercialization@pnnl.gov.

Advantages

ShAPEretro enables higher-performance extruded products and integrates with manufacturers’ current equipment. This ShAPE retrofit solution accelerates the modernization of extrusion operations, reduces the overall cost of ownership, and expands the competitive capabilities of conventional manufacturing lines. ShAPEretro optimizes existing assets and reduces implementation risk. This technology provides a transformative pathway for industries to access next-generation extrusion capabilities affordably and with minimal operational disruption.

- Retrofit Integration: Enables rapid market adoption without the need to replace existing extrusion presses.

- Cost-Effective Upgrade: Eliminates the need for alignment systems and new structural platforms.

- Operational Simplicity: Separation of rotational and linear loads shortens the load path and reduces engineering complexity.

- Reduced Overall Impact: Cuts power consumption by removing the need for billet preheating and streamlining the process.

- Enhanced Product Quality: Enables the production of high-strength, fine-microstructure extrusions previously not achievable on legacy equipment.

State of Development

Lab Scale