Technology Overview

This technology introduces microbial consortia capable of programmable output through interactions between photoautotrophic and heterotrophic organisms. It addresses significant sustainability challenges by optimizing microbial cooperation for enhanced biomanufacturing.

The biomanufacturing industry faces issues with efficiency and stability in industrial microbial processes. These challenges lead to increased costs and inconsistent product yields. The innovative microbial consortia developed at Pacific Northwest National Laboratory addresses these barriers by engineering robust interactions between different microbial species.

At the core of this technology is a consortium comprising of engineered strains of Synechococcus 7002 that produce and secrete increased amounts of sugars and heterotrophic species tailored to utilize these sugars. The system utilizes high-salt medium conditions to maximize sugar production, driving metabolic activity of linked microbial systems. By precisely controlling communication and metabolic exchange between microbes through synthetic riboswitches and signaling molecules, such as acyl homoserine lactone, the consortium achieves enhanced process stability and productivity.

Scientists at Pacific Northwest National Laboratory have fine-tuned this cooperative system to efficiently partition niches and optimize resource usage among microbial species. This advancement increases the overall stability and output quality of biomanufacturing processes, leading to significant reductions in operational costs and improvements in product consistency.

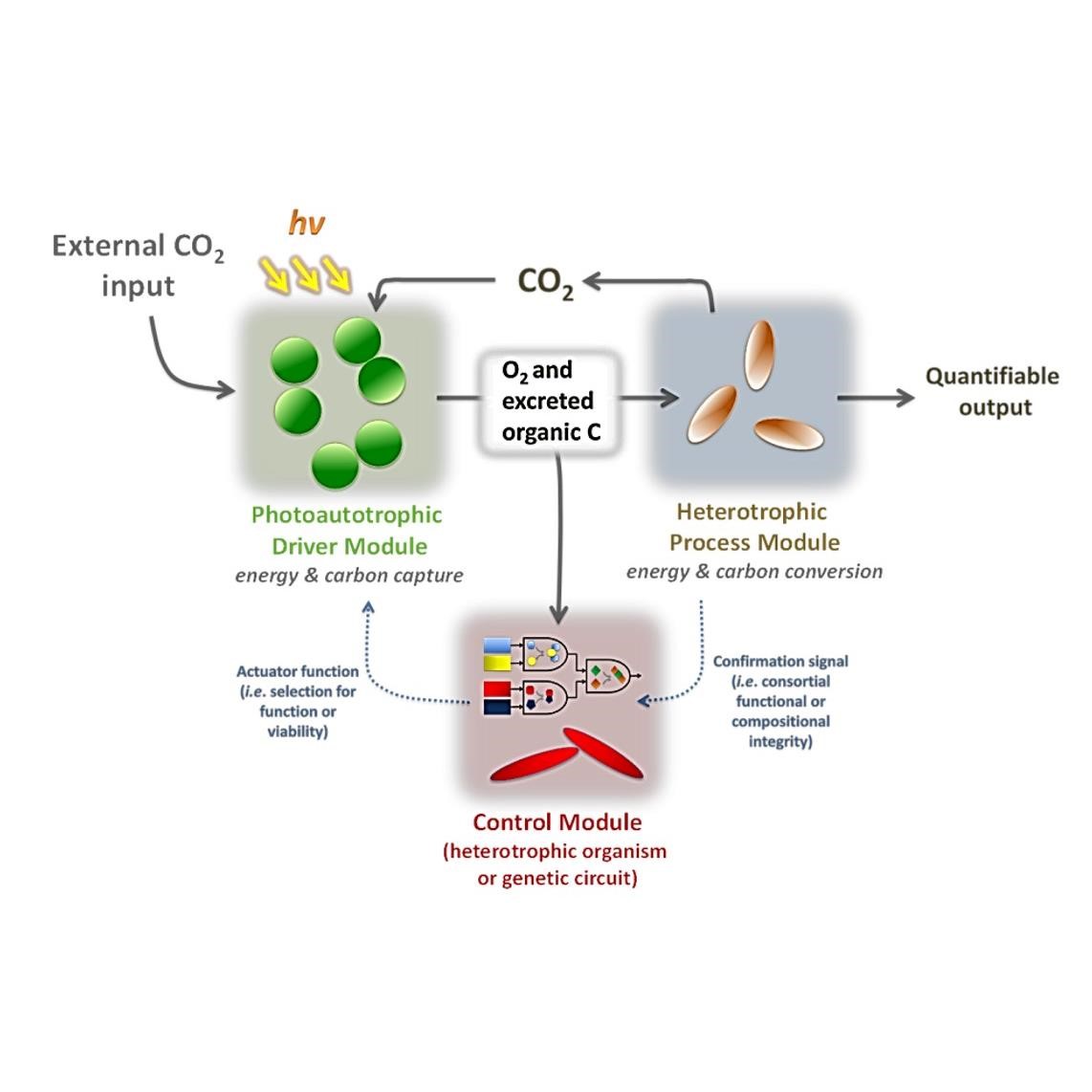

This approach is comprised of three components. A photosynthetic module generates carbohydrates from CO2 and light. Carbohydrates are converted to many different forms by a heterotrophic process module. Carbon sources from both modules then support a control module that can be modified genomically to carry out a process of interest. The control and heterotrophic modules can also support the photosynthetic module by providing CO2 as a carbon input. Such a system is designed to be balanced so that no one component outcompetes the other. It is driven by light inputs with minimal carbon, maximizing the efficiency of the control module and the processes it carries out.

APPLICABILITY

This technology is applicable in various industrial biomanufacturing sectors, notably in the production of biofuels, bioplastics, and high-value chemicals. Potential users include companies engaged in sustainable manufacturing processes which require stable microbial production systems.

Advantages

- Enhanced stability and efficiency of microbial consortia

- Increased production yields of bioproducts

- Cost-effective and sustainable biomanufacturing processes

- Precisely programmable microbial functions

For more information, please contact: commercialization@pnnl.gov.