Technology Overview

What if we could join high-strength, dissimilar metals, using a mechanical interlock with a metallurgical bond with no costly rivets, no welds, and no filler metal… in milliseconds? Researchers at Pacific Northwest National Laboratory (PNNL), enabled by funding received from the Transportation Technologies Office Joining Core Program and LightMAT, have developed a High-Velocity (HiVe) joining process to do exactly that, making HiVe joints 1.5× stronger than flow-drill screws and 8× stronger than conventional clinch joints.

HiVe joining is a breakthrough technology that enables both product differentiation and a reduction in the manufacturing cost of complex engineered systems and subassemblies composed of dissimilar and difficult-to-weld metals, where conventional joining methods fall short. By harnessing extreme kinematics and material flow behavior, HiVe delivers a robust mechanical joint that incorporates a metallurgical bond at the joint interface, with the added benefit of improved workplace conditions—unlocking new design freedom for next-generation manufacturing.

Lightweight, multi-material vehicle designs are critical for improved occupant safety and efficiency, while addressing the manufacturer’s need to increase market share by offering affordable transportation solutions. Joining advanced metals like cast aluminum to high-strength steel is challenging due to the limited ductility inherent in these types of materials. HiVe joining results in high thermal gradients and minimal heat input, enabling assembly of high-strength and low-ductility materials without cracking and embrittlement of the heat-affected zone. The heat input associated with HiVe joining is approximately an order of magnitude less than fusion processes, effectively eliminating the heat-affected zone and delirious impact on the structural strength of the assembly. The “jetting” characteristic associated with high shear velocity enables use of rivet and striker materials similar in hardness to the materials being joined, expanding the material set for joining applications from 800 megapascal to 1,700 megapascal. The unique process was developed at PNNL using a multiscale modeling framework: macro-scale simulations optimize deformation characteristics, while atomistic models predicted bonding at the atomic level.

HiVe comes in four main variants suitable for a wide range of joint configurations: HiVe-Clinching for fast, consumable-free sheet joining; HiVe-SPR (self-piercing rivet) for high-strength multi-material stacks using SPR rivets; HiVe-Solid Rivet for demanding structural applications; and HiVe-nailing for blind joining, maintaining dimensional alignment before the adhesive cures. HiVe has been successfully demonstrated in hybrid joining configurations that integrate structural adhesives, combining metallurgical bonding with a mechanical interlock bonding to further enhance joint strength, stiffness, sealing, fatigue performance, and structural strength. Conventional joining methods require drilling a clearance hole and T7 heat treatment before assembly, which increases the cost and cycle time.

Lap Shear and Cross Tension coupon tests indicate HiVe joints can be 1.5× stronger than flow-drill screws and 8× stronger than conventional clinch joints, all while improving recyclability and corrosion resistance, as well as maintaining the established Bill of Process and compatibility with modern automotive manufacturing assembly methods. A materials stack that includes as-cast automotive castings with <3% ductility and 1,700 megapascal advanced high-strength steel sheets have been successfully joined using the HiVe process—in a single step.

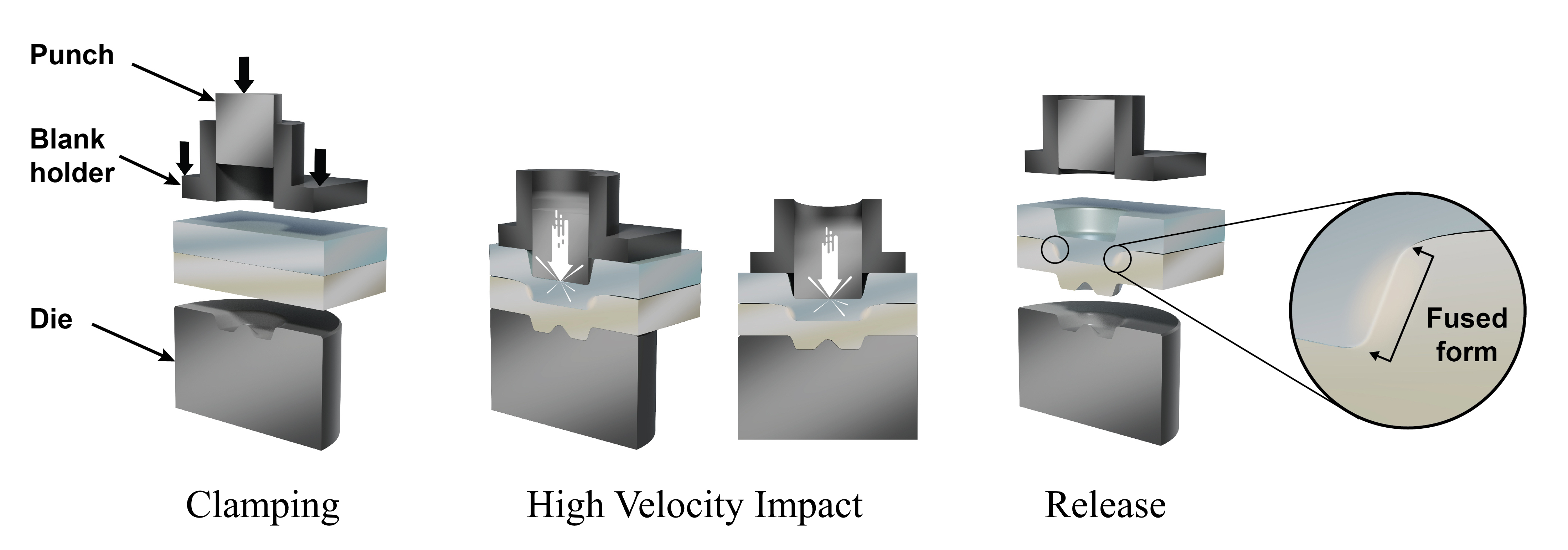

HOW IT WORKS

Akin to explosive bonding, shear velocities associated with HiVe result in localized jetting and adiabatic shear, disrupting surface oxides and enabling solid-state bonding. Unlike explosive bonding processes—which rely on jetting imposed by extreme velocities—HiVe joining harnesses the same fundamental physics in a safe, repeatable, and factory-deployable process using compact, precisely tuned electro-mechanical systems.

The fundamental mechanism underlying HiVe processes is the conversion of kinetic energy into localized heat and plastic deformation at the joint interface. Similar to pressing and sliding hands together, increased normal force and relative velocity elevate temperature and reduce flow stress, allowing the materials to deform, interlock, and in most cases, bond metallurgically before all within less than a second.

Strength tests show performance comparable to or better than conventional fasteners, with failures occurring in the surrounding material rather than the bonded interface. Results concluded that HiVe combines the speed of mechanical fastening with the strength of a fully welded joint, at a lower cost.

APPLICABILITY

HiVe is well suited for automotive vehicle structures, aerospace components, and other systems where strong, rapid, low-heat joining is essential. By creating a rivet-strength joint without added materials, the technology opens a new pathway for manufacturing efficiency. It occupies a unique space between explosive welding and mechanical fastening, achieving the speed and practicality of rivets while providing the strength and microstructural continuity typically associated with metallurgical bonds.

For more information, please contact commercialization@pnnl.gov.

Advantages

HiVe joining technology delivers up to 1.5× the strength of flow-drill screws and 8× the strength of conventional clinch joints, while enabling robust, reliable joining of dissimilar materials such as steel and aluminum, unlocking new lightweight design possibilities without compromising performance. Other advantages include:

Reduced Manufacturing Cost

- Elimination of consumables with HiVe Clinch process (rivets and fasteners).

- SPR, solid-rivet, and nailing processes still require a rivet, though the cost is still much cheaper.

- Reduction in process cycle time.

- Reduction in energy usage (F-temper vs. T7 Heat Treatment).

Compatible with Current Bill of Process

- Metallurgical bond not affected by using structural adhesive.

- HiVe C-frame compatible with existing robotic framing stations.

New Product Opportunities Based on Expanded Material Set

- AHSS and UHSS 1,700 megapascal.

- Enable application of cast giga assemblies vs. giga castings.

- HiVe process independent of stacking order.

- Enable increased use of Gen3 steel.

- Enable increased use of low-cost aluminum extrusions.

- Enable increased use of low-alloy content, low-cost boron steel.

- Accelerated manufacturing cycle times.

- Optimized use of adhesives and simplified curing cycles.

State of Development

Available for licensing in all fields