Technology Overview

An innovative nuclear magnetic resonance (NMR) probe design optimizes temperature distribution across samples, enabling high-resolution analysis at elevated temperatures (350°C). This technology is crucial for advanced NMR spectroscopy, minimizing temperature gradients and enhancing data accuracy, especially for high-stakes industrial applications.

The field of NMR spectroscopy often grapples with significant temperature-dependent challenges that can skew data interpretation. Traditional systems face inhomogeneous heating and inefficient heat transfer, leading to considerable temperature gradients across samples. These gradients adversely affect the resolution and reliability of critical NMR parameters such as spin–lattice relaxation time (T1), spin–spin relaxation time (T2), and chemical shift.

Industry professionals often encounter difficulties with sample stability and reaction analysis at high temperatures due to these gradients. Existing solutions are typically limited and expensive and require specialized components that do not address the root issue of temperature homogeneity. The technology developed at Pacific Northwest National Laboratory addresses these barriers by incorporating controlled heating mechanisms for both variable temperature (VT) gas and bearing gas flows in NMR probes.

The innovative NMR probe design allows for a maximum operational temperature of 350°C with standard rotors and components. Computational fluid dynamics simulations coupled with empirical adjustments are used to ensure that the temperature gradient within the sample space is below 3°C. This optimal control is achieved through selective heating of both VT and bearing gases, enabling uniform temperature distribution, even at high temperatures. The system is compatible with pressurized rotors that hold up to 400 bars at room temperature, facilitating previously impossible in situ NMR studies of mixed-phase reactions.

By significantly reducing the temperature gradient, Pacific Northwest National Laboratory’s technology enhances the accuracy of NMR data, resulting in more reliable phase transition and reaction analysis. This advancement is poised to affect various industrial applications that rely on precise temperature control during high-resolution NMR experiments.

APPLICABILITY

This technology is highly applicable in the fields of chemical analysis, materials science, and industrial catalysis. Potential users include research laboratories, industrial research and development departments, and manufacturers that require high-precision NMR data at elevated temperatures.

DESIGN

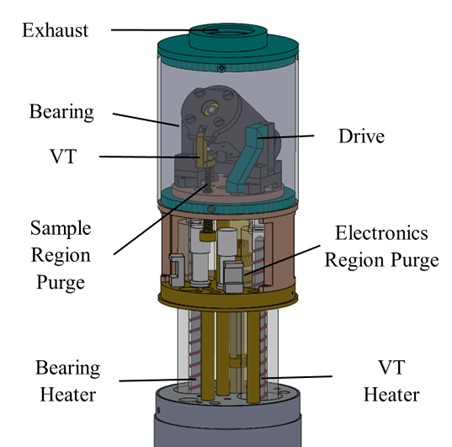

This technology is a rotor housing assembly for NMR spectroscopy. An elongated rotor has a distal drive end, a proximal end, and an internal sample space positioned along its length between the drive and proximal ends. The rotor is drivable about a rotation axis by a drive gas flow. The rotor housing has an interior space in which the rotor is partially received. At least one first heated gas flow inlet is positioned opposite the internal sample space, through which a first heated gas flow is controllably flowable into the interior space to heat it and the rotor. A pair of spaced-apart second heated gas flow outlets are axially spaced from the first heated gas flow inlet to controllably convey a second heated gas flow to heat distal and proximal areas of the sample space and thereby minimize a temperature gradient extending axially within the sample space.

Advantages

- Reduces the temperature gradient to below 3°C across the sample space

- Achieves high operational temperatures up to 350°C using standard NMR components

- Is compatible with pressurized rotors for in situ studies of mixed-phase reactions

- Enhances the reliability and resolution of NMR spectroscopy data

For more information, please contact: commercialization@pnnl.gov